CROSSOVER M

CROSSOVER M 6m

KEY CHARACTERISTICS

Small packaging - Strong and light aluminum structure - Premium fabric materials - All weather resistant - Various anchoring options - Fits Layher scenarios

TÜV certification - Quick and easy installation - Customizable - Digitally printable cover - Endless connectable

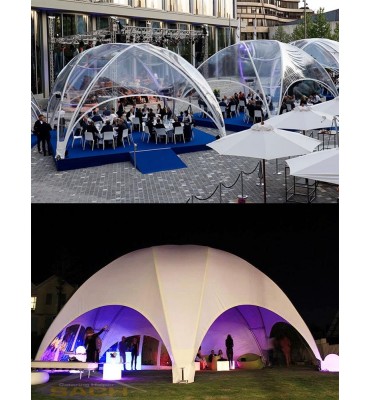

Multiple mounting options up to 400 kg - All-weather resistant -30 to +70 - An ideal tent for any event, wedding, advertising, concert, hotel, etc.

Compact and light in transport. - It Easy to assemble with few people and without working with large cranes.

Strong and resistant. - Available in 4 sizes: 6m - 8m - 10m - 17m - It is a modular tent, you can put together various sizes in an infinite way.

Download our complete price list in the attachment

Product customisation

Don't forget to save your customization to be able to add to cart.svg) Shipping Policy

Shipping Policy

Pending valuation under budget

Working Hours:

Working Hours:

10:00 a.m. to 7:00 p.m. - +34 642 29 19 30 / + 351 934618402

Personalization

Personalization

We Are In Contact At All Times To Customize Your Products

CROSSOVER M

KEY CHARACTERISTICS

Small packaging - Strong and light aluminum structure - Premium fabric materials - All weather resistant - Various anchoring options - Fits Layher scenarios

TÜV certification - Quick and easy installation - Customizable - Digitally printable cover - Endless connectable

Multiple mounting options up to 400 kg - All-weather resistant -30 to +70 - An ideal tent for any event, wedding, advertising, concert, hotel, etc.

Compact and light in transport. - It Easy to assemble with few people and without working with large cranes.

Strong and resistant. - Available in 4 sizes: 6m - 8m - 10m - 17m - It is a modular tent, you can put together various sizes in an infinite way.

Download our complete price list in the attachments

Superior quality fabric materials

- For the manufacture of covers and side panels

We only use high quality materials from brands like Ferrari and Sergio Mehler.

Of course these are flame retardant materials according to the

standard DIN 4102 B1, M2.

By default we offer the following materials for the covers and side panels:

* Mehler Airtex magic FR:

- Airtex is very popular with our customers for its soft textile-like appearance and lightweight (330g / m2),

which helps with faster assembly times. Because the material is translucent, it allows light to

pass through more easily allowing the crossing to illuminate from the inside very well at night.

Airtex is supplied in white and optional in black.

* Mehler Valmex Tivoli:

- This medium weight (582g / m2) fabric has a high gloss finish and is available in various colors, including silver.

* Ferrari Stam 6002:

- The matte texture and light coating of this material give the product a luxurious look. It is available in 16 distinctive colors and is 100% recyclable.

If the standard range does not contain the definitive material for the intended application, we are more than willing to find a joint alternative that responds to your specific needs, please contact us !!

* High-resolution digital printing:

- With the digital printing of the covers and sidewalls we offer you the possibility of customizing the product

if desired, the covers can be provided with a print on the outside and the side walls can be

print double-sided.

* Layout:

- For graphic design, you can use our design templates. In the design template, the desired design can be inserted.

a presentation of the edited design template will be processed by us when printing.

* Full print or print logo:

- In addition to printing a full cover, it is possible to provide only the sides with a logo.

This translates to lower printing costs.

The maximum width of the logos is 235cm.

In the template layout, the positions and boundaries of the logos are displayed.

* Quality:

- For printing, we use the latest Vutek printers that can print at a resolution of up to 1000 dpi. Print quality is determined by the quality of the supplied design. Texts, logos, etc., which are supplied in vector format will deliver a good crisp print result. Pixel files like photos should have a resolution that is as high as possible. Since the design is delivered at a 1:10 scale, the resolution of the final print will be a factor of 10 less than the resolution of the design template. The resolution of the final print must be at least 25dpi. The images in the design template must therefore have a minimum resolution of 250dpi.

* Materials:

- Default Airtex material with a white or gray back is used for printing. If the product is lit from the inside, the print is beautifully lit. This effect is less when applied with an Airtex starter.

- When it is not suitable that the print shines through, for example for double-sided printing, You can choose for the block out material. Relative heavy material (780g / m2) contains a special layer that blocks light.

- If the sides are printed on two sides block out material, we recommend using PVC Frontlit material for the cover because this material has the same light gloss finish. Frontlit (450g / m2) is slightly translucent.

- As an option, printing on black Airtex material is possible. This is done by applying a white coat before printing in color. This method is only suitable for logo printing.

* Reinforcements:

- The edges of our products are reinforced with PVC to ensure a long life. These reinforcements cannot be printed. However, we offer the possibility of applying them in black or white.

* painted logos:

- Since not all materials are well printable, we offer you the possibility of applying logos with special epoxy paint. Maximum size: 150x150cm. For this, the logo can only contain a few different colors and cannot contain gradients.

* Display:

Since the beginning of 2014, we have offered an online configuration tool that offers the ability to view the design in real-time, giving you a good idea of the final result in 3D.

Have questions about digital printing or do you need help with your product design? Please don't hesitate to contact us!

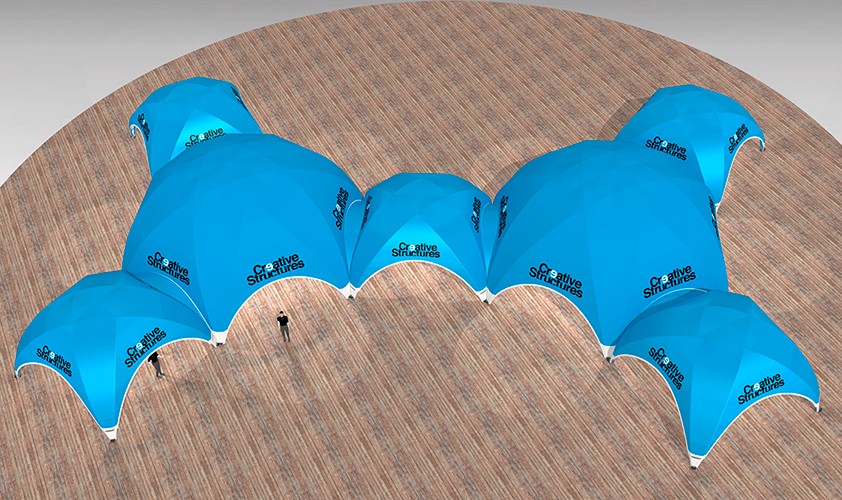

* Endless connectivity.

The Crossover is a modular product without corset lines and therefore can be connected endlessly on all sides. This allows for large area coverage and fun setups.

Two crossover units can be connected to each other, with a connecting channel that can be easily applied by using YKK zippers.

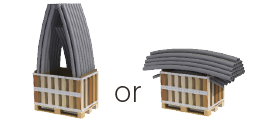

Compact transport volume

< / p>

< / p>

- During the development of the Crossover we made an effort to minimize the volume of transport and weight. This has resulted in the fact that the whole Crossover structure only takes up the space of one Euro-pallet (120x80cm) when transported.

- For transport and storage, we have developed a special box that allows the tubes to be stacked vertically and horizontally. When stacked vertically, the box also provides space for the cover and side panels.

- When stacked horizontally, the structure can also be transported by a van or small trailer. Thanks to an access door in the frame, the parts under the tubes remain easily accessible and the box can remain in the van during the installation of the frame.

- The transport box is equipped with wood that has had a heat treatment in accordance with the ISPM 15 standard and therefore the box is suitable for international transport.

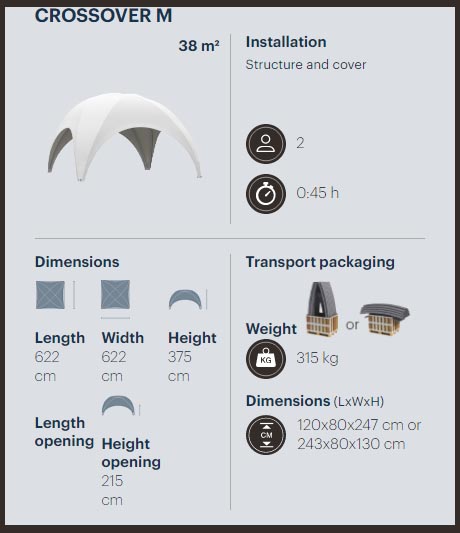

* Dimensions and weights

Packaging - tubes stacked vertically:

120 x 80 x 247cm (lxbxh), 291kg

Packaging - horizontally stacked tubes:

245 x 80 x 140cm (lxbxh), 291kg

Cover Packaging (Airtex):

45kg

Side Panel Packaging (Airtex):

8kg

Connection gutter packaging:

2kg

Ballast support:

100 x 94 x 7cm (lxbxh), 25kg

ballast interface - 1 unit Crossover:

50 x 23 x 6cm (lxbxh), 6kg

Ballast interface - multiple Crossover units:

71 x 71 x 6cm (lxbxh), 22kg

Anchor pin:

3.5 x 100cm

Distinctive options in the finish of the Structure

- The aluminum frame tubes are supplied with a brushed surface. For an additional high visual impact of the frame the tubes can be powder coated or anodized.

- Powder coating, in this way the tubes get a double layer Dupont coating in a RAL color of your choice.

When we anodize the tubes will have a hard oxide layer with a matte finish. As an option, you can choose to color the oxide layer.

Would you like personalized advice and talk about your specific wishes? Please don't hesitate to contact us!

TÜV - certification in process.

- The TÜV approval is intended to guarantee the structural safety of temporary structures. During approval, the strength of the product was investigated in detail according to standard NEN-EN 13782. In addition, topics such as fire protection are reviewed in accordance with DIN 4102. The TÜV Certification of the Crossover L represents professional safety and reliability. Certification is in the process now. We will inform you when the certification is complete with our newsletter.

- The certification applies to free-standing and connected crossover units and therefore includes all possible configuration options. In addition, the ballast system is also included.

- The certification applies to free-standing and connected crossover units and therefore includes all possible configuration options.

- In addition, the ballast system is also included.

The TÜV-product book can be put in the name to be used as a building permit.

400kg to install on the frame.

- Four mounting points are provided on the top of the frame that can accommodate hardware for 400kg total. This makes it possible to erect a sound and light shelf or a stylish chandelier on the frame.

- The additional 400 kg payload can also be used as an additional snow load.

- An M10 mounting point is provided at each corner to install eg a monitor or light fixtures. For displays with mounting points in accordance with the VESA Directive, we offer an optional universal mounting kit.

Quick and easy assembly

- The Crossover M can be easily assembled by two men within 45 minutes with a telescopic lift or crane. As the structure is built from the base in layers, the need to work at height is eliminated. Due to the limited size and weight of the components, no tools are required for their assembly and since they are very easy to handle, height and muscle strength are not necessary.

- Assembly of the structure without a lift or crane is possible and in many cases often faster, however, it is not recommended because it may result in unfavorable forces being applied to the structure which can lead to damage.

- Ask us for the detailed construction manual.

Once the assembly is done and the structure is anchored, the roof is installed. If desired, the side walls can also be mounted.

- Crane requirements:

Minimum lift height:

450cm

Minimum safe workload:

250kg

Light but very robust aluminum structure.

- The frame is constructed of oversized rolled aluminum tubes. By using so-called 6082T6 aluminum, the tubes are light in weight but as strong as steel. The short length of the tubes contributes to the compact transport volume of the Crossover.

The aluminum tubes are joined together with connectors. The connectors consist of S355-extra strong steel tubes, with 3D precision - cut with the laser.

The connectors are robotically welded and galvanized. All these guarantee optimum quality, long life, and a good fit.

- High-quality marine-grade stainless steel cables provide ultimate strength and stiffness while maintaining the low weight of the structure. By tensioning the lower cables, all the cables are subjected to tension and the structure will obtain its rigidity.

- The construction is calculated in detail according to the 13782 NEN-EN standard and the German TÜV certification is in process.

This ensures professional safety and reliability.

For an additional high visual impact of the structure, the tubes can be powder coated or anodized.

* Dimensions and weights

38m 2

622cm

375cm

215cm

Complete and hermetic closures

- The crossover can be completely closed with side panels that can be easily installed with YKK zippers. The panels are tensioned at the bottom with tensioners at the feet of the structure and, optionally, at the intermediate anchoring points on the floor surface.

- If desired, the side panels can be provided with windows and/or a door.

The door is created by opening the two vertical zippers and rolling the panel up.

- The side panels are digitally printable on both sides.

Window panels can only be printed on the outside.

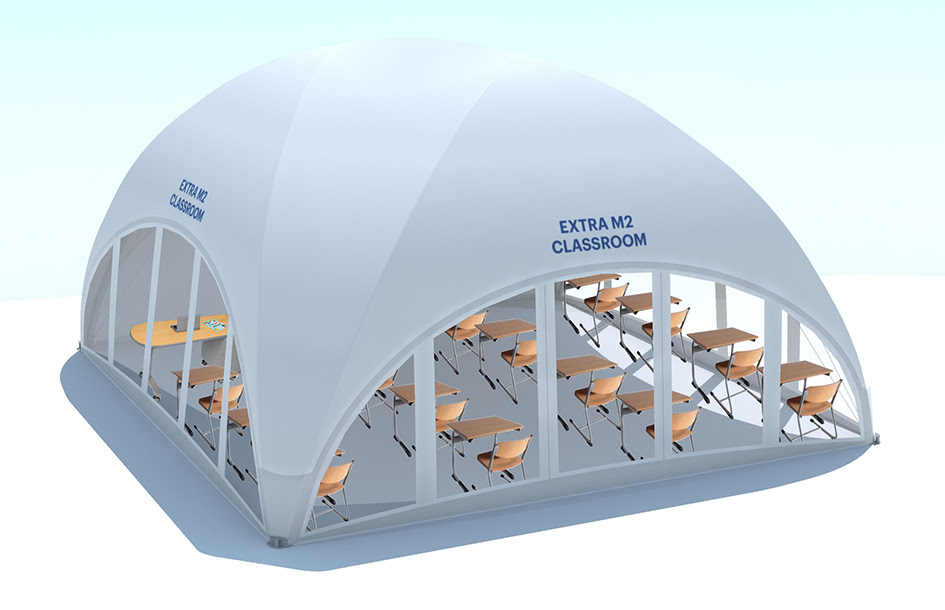

Can be mounted on a platform

- The dimensions of the Crossover are chosen so that the product fits perfectly in the most used classification systems such as Layher (2072mm stitches/non-metric).

For this, the Crossover can be used as a stage with a ceiling or as part of a VIP deck.

- By means of standard stage clamps, the crossover can be attached to the vertical beams of the deck. The platform can then be used as an anchoring foundation.

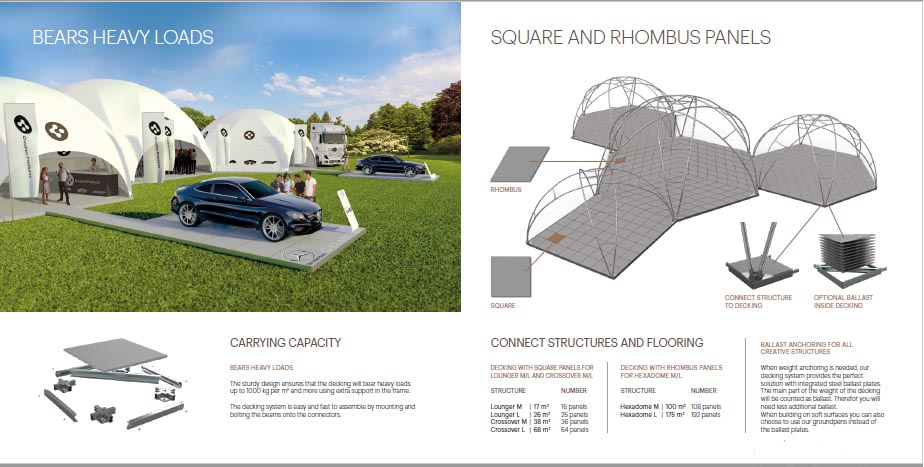

Multiple anchoring possibilities

- For a safe application of the Crossover, it has to be well anchored to the ground surface. There are several anchoring options provided for both hard and soft surfaces.

The crossing is basically only anchored at the four corners of the frame. If desired, additional intermediate anchor points can also provide additional support to the walls.

- Anchoring with anchor bolts

This method is ideal for installation on soft surfaces. The pin can be installed manually with a heavy hammer or mechanical device.

Through an optional accessory, the pin can be easily pulled out of the ground.

- Anchor with bolted joints

With this method, the feet of the structure is fixed on a hard surface with concrete screws, anchor bolts, or special plugs.

This anchoring method is ideal for installation on hard surfaces where they can be drilled.

- Anchor with ballast

In situations where anchoring to the ground surface is not allowed, anchoring can be accomplished by applying ballast.

We have developed a ballast system that uses commonly available concrete ballast tiles and does not interrupt connecting crossover units and installing the side panels.

If desired, the ballast tiles can be covered so that they can be used as a bench or demo table.

- The anchor in a stage

If the Crossover is used as a covered stage or as part of a VIP deck, the stage can be used as an anchor.

By means of standard stage clamps, the crossover can be attached to the vertical beams of the stage.

CUSTOMIZATION

Design Templates

Customize your cover. Design templates to create your design are available upon request.

.jpg)

Data sheet

- MARQUEES STYLE

- CREATIVE STRUCTURES